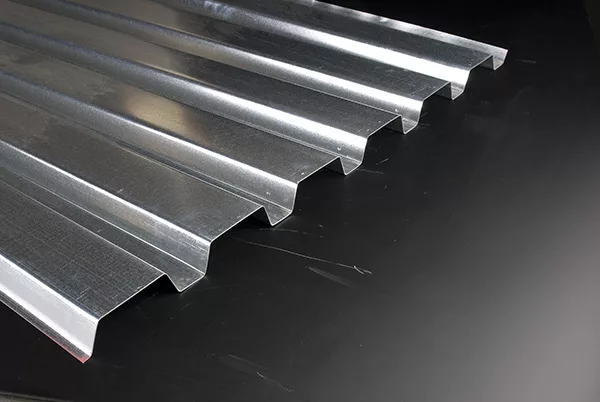

Type B Roof Deck

Type B Roof Deck (Wide Rib)

80 KSI Metal Roof Deck

Specifications and Span Chart below

WHAT IS B DECK?

B Deck is the most commonly used roof deck for new construction projects; this is because B Deck is the most efficient 1.5” deep steel roof deck section. Compared to Type A roof decks and Type F roof decks, Type B metal roof decks have the highest strength-to-weight ratio. As with all steel products, the lighter the section, the more economical it will be. And since B decks can carry higher loads at longer spans than A decks and F decks, the steel supports below the metal deck can be spaced further apart. The result? A larger support spacing results in fewer supports and more savings for the building owner. Check out our breakdown of Type B metal roof deck dimensions below.

B DECK (WIDE RIB)

METAL ROOF DECKING DIMENSIONS & INFO

PRODUCT INFO

Industry Designations

Type B Deck

Wide Rib

WR

Type B Deck is the “original term” for this deck profile, though recently, the Steel Deck Institute has promoted the more descriptive name, “Wide Rib Roof Deck,” or “Type WR.” Type B is also sometimes referred to as “Type B Metal Roof Deck.”

Finishes

Prime Painted

Galvanized

In contrast to galvanized finishes, prime painted grey over bare steel is the most economical finish available for Type B roof deck. This finish typically provides adequate temporary protection to the base metal during construction, and will protect the base steel indefinitely in a properly enclosed, dry interior environment.

However, if the interior environment is more aggressive, or if greater corrosion protection is required during construction, then a galvanized coating in either G60 (0.6 ounces of zinc per square foot of metal) or G90 (0.9 ounces of zinc) is recommended. Government projects typically require a G90 galvanized finish.

In order to help avoid field paint adhesion issues with galvanized deck, it’s recommended that a galvanized and prime painted finish be used when galvanized deck is to be field painted.

A white primer is also available for the underside of the B deck, but, if a field coat of paint is not going to be applied, a higher level of care must be taken to ensure that the steel roof deck is not exposed to moisture before it is installed and covered in a dry environment. In fact, if a white bottom finish is intended to be left exposed, the best finish to use is galvanized (G30 or heavier) and painted white.

Gauges

22

20

18

16

Type B roof deck is most readily available with material thicknesses defined by the even gauges 16, 18, 20, and 22. These correspond to design thicknesses of 0.0598”, 0.0474”, 0.0358”, and 0.0295”, respectively. While Type B metal decks can be produced in any material thickness between 16 and 22, defining an “odd” or “special” gauge will make the deck much more difficult to source.

| No. of Spans | Deck Type | Max Const. Span |

| 1 | B22

B20 B18 B16 |

5'-7"

6'-5" 7'-5" 8'-8" |

| 2 or more | B22

B20 B18 B16 |

6'-0"

6'-6" 7'-5" 9'-4" |

Type B Roof Decks

Compared to other roof decks, such as Type A and Type F, Type B roof decks have a higher strength-to-weight ratio, are more economical, and carry higher loads at longer spans. Building owners can save money by purchasing fewer supports since steel supports can be spaced further apart with Type B metal decks.

To illustrate this point, consider the Factory Mutual maximum deck spans. For 22 GA 1.5 B Deck, the maximum span is 6’-0”, but the maximum span falls to 4’-11” for 22GA 1.5 F Deck and only 4’-10” for 22GA 1.5 A Deck. The Steel Deck Institute Maximum Construction spans for two or more spans show a similar pattern. These maximums are 6’-11”, 5’-3”, and 3-9” for Type B, Type F, and Type A, respectively.

Though the capacities for Type F and Type A decks are lower than those for Type B decks, the main objective when these metal deck profiles were developed was to maximize the width of the top flange to provide the maximum amount of support for the roofing insulation that would be installed on top of it. As roofing materials improved, the width of the top flange was reduced, increasing the efficiency of the section from Type A to Type F deck and finally from Type F to Type B deck.

Type B roof deck has a higher load capacity than Type F and Type A; at mid-span, the top flange of the metal deck is in compression. When thin metals like 22 gauge or 20 gauge (.0295” and .0358” thick) are compressed, it is difficult to predict how and when they will buckle. However, it is known that bending thin metals strengthens it significantly. While the moment of inertia of the bends can be reliably calculated, the moment of inertia of the compression flanges is more complex. The material closest to the bends will resist buckling better than the flat material further away from the bends. Type B roof deck has the smallest top flange (3.5” versus 4.25” for F deck and 5” for A deck), and more of the top flange is effective in resisting the compressive forces that result from bending.

Supports are often spaced at 5’ to 6’ on center for 22GA Type B metal roof deck. Therefore, D-MAC stocks sheets that are multiples of these metal roof decking dimensions, and we can cut them to any length. B Deck is also known as wide rib roof deck, and when using B deck to cover skylights, note the maximum unshored spans for one (1) span. As shown in the Maximum Construction Span table on this page, the maximum span for one span is 5 inches shorter than the maximum allowed when each deck sheet covers two or more spans. For additional questions about Type B metal decks or wide rib roof decks, contact D-MAC Industries.

"*" indicates required fields