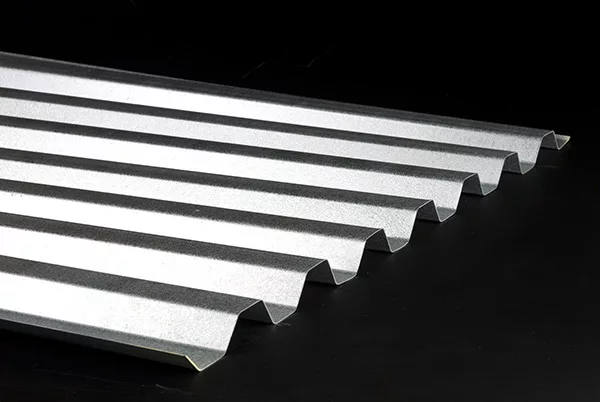

1″ Form Deck

FORM DECK PRODUCT INFO

PRODUCT INFO

Industry Designations

1.0C

1.0FD

CF 7/8

HD

HF

TF75

UFIX

Finishes

Galvanized

Gauges

26

24

22

20

| Cover Widths | Height (Min.) | Pitch (Rib Spacing – Center to Center) |

| 36 in | 15/16 in | 4 in |

15/16” Form Deck

Non-composite form deck is used when steel or concrete composite is not required. Often used in floors and stairways, 15/16” form deck is ideal for heavy-duty applications. The 1” form deck provides a strong base for forming slabs and serves as a permanent steel base for concrete floor slabs. With over 30 locations, our team always goes the extra mile for our customers, which is why so many builders, contractors, and engineers rely on us for the best customer service in the steel deck industry. Learn more about our 15/16” form deck, including its specifications and applications, then contact us for a quick and easy quote.

15/16” Form Deck Specifications

The 15/16” form deck is a metal form deck that covers 36 inches and features a rib spacing of 4 inches. This non-composite form deck is available in 26, 24, 22, and 20 gauges and comes in a galvanized finish, the standard in the steel decking industry. The galvanized finish is ideal for high moisture environments and ensures a durable and permanent application. It is also used for roof deck systems where the form deck is used to carry a lightweight insulating concrete member. Every form deck from D-MAC Industries is crafted per the Steel Decking Institute (SDI). Use our online guide to match an existing non-composite floor deck.

Form Deck Installation

Qualified and experienced workers should install all form decks. We will ask the decking contractor to approve all shop drawings before installation, and the decking should be installed under approved erection drawings.

The SDI recommends not applying sealants at the ends or side laps of the form deck, as this may impair its intended structural purpose. When creating a workable platform, ensure the deck is properly fastened to the support members.

When installing a 1” form deck:

- Make sure that hoisted loads are balanced

- Do not stand under loads being hoisted, and always keep loads in view

- Use proper hand signals to crane operators

- Never use single-span bundles as a working platform

- Check that cutouts and openings are adequately supported and guarded

- Wear eye protection near welding

Handling and Storing 1” Form Deck

The form deck is banded into bundles that can weigh several thousand pounds. Each bundle is limited to a maximum of 4,000 pounds for the deck to be applied to joists. When storing the form deck, elevate one end to provide drainage. Protect bundles of form deck against condensation and moisture with a ventilated waterproof covering and protect the form deck from snow and salt.

1.0 form decks should be stored off the ground and secured by bundle straps or banding to prevent damage. Tightness should be periodically checked, and additional securement should be used as needed. Per the Steel Deck Institute (SDI), bundles should never be placed on unbolted frames or unattached or unbridged joists. If galvanized products are stored outside, some oxidation may occur on the surface. This does not affect the structural integrity of the steel. Our team can help make recommendations to prevent the form deck from oxidizing to maintain its aesthetically pleasing appearance.

The D-MAC Industries Advantage

D-MAC Industries is a family-owned and operated business providing exceptional customer experience. We understand your unique needs and can answer any questions you may have regarding the 1.0 form deck and accessories (such as pour stops or ridge and valley plates) needed to complete your project. We offer same-day fulfillment and shipment of form decks, prompt deliveries, and no-hassle pickups so you can quickly get the products you need. Our experienced team has 30 to 40 years in the steel decking industry and is ready and available to assist you! With D-MAC Industries, you can get all the floor deck products and accessories you need on time. Contact our team using our convenient online form, or call us today!

"*" indicates required fields